Most obvious benefit compared to traditional thermal magnetic MCBs is that the HY-MAG circuit breakers are not sensitive to ambient temperatures. They keep rated current regardless of the ambient temperature. Certified to -40 / +85 degrees C.

Thermal-Magnetic MCBs on the other hand only work properly in room temperature and already at 30 degrees they can only carry ~ 75% of the rated current. This means that this type of MCBs needs to be de-rated, I.e. you need to use a higher rated MCB than you actually need. This can have large impact on your cost for cables and busbar systems. And of course, you get less accuracy in your application.

|

|

|

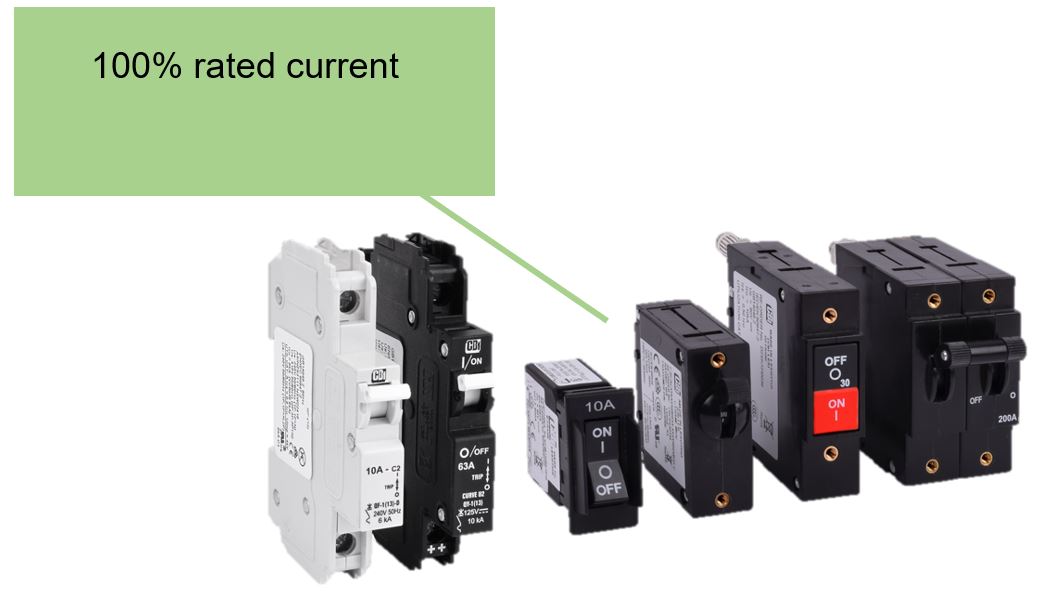

| Thermal magnetic MCBs, are only allowed to be loaded continuously to 80% of the rated current (the 80% de-rating rule) while our products are designed to be loaded at 100% of rated current. |

|

|

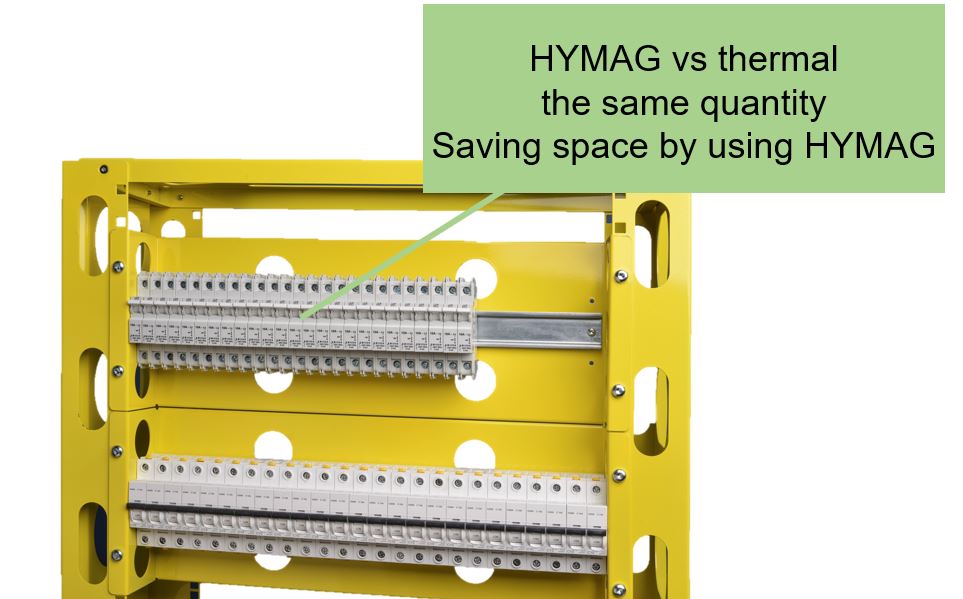

The temperature independence give us the possibility to build a thinner circuit breaker. Accordingly, our DIN rail mounted circuit breakers have 13mm instead of common 18mm. Keep in mind also that space saving is cost saving in many cases. |

|

|

| When a thermal magnetic MCB trips due to an overload the bi-metal strip needs to be cooled down before it can be switched on, this is not the case for a HY-MAG product. Your important loads can immediately be switched on again. |

|

Thermal magnetic MCBs are in general designed for AC but in many cases also used for DC. A DC voltage is more difficult to handle for a circuit breaker, since there is a risk of the arc not being extinguished when switching the circuit breaker. Therefore, our HY-MAG products are designed in different ranges, dedicated for DC or AC depending on your application.

|

|

| It’s very important to not waste energy, both from an environmental point of view as well as from a cost point of view. The bi-metal strip on a thermal circuit breaker always create a certain heat which means losses. In general, the internal resistance in a HY-MAG circuit breaker is around 45% lower. |

|

The sensing device on a Thermal magnetic MCB is the bi-metal strip. This will over time be exposed to air, humidity and different types of pollution that will affect the functionality over time. This is not the case for the HY-MAG circuit breaker since the sensing mechanism is hermetically sealed

|

|

| In general our products are certified both to the highest European industrial standard for circuit breakers, IEC 60947-2 as well as UL listed according to UL489 or UL489A. |

|

|

As mentioned above, one of the key benefits with HY-MAG MCBs is that they keep their rated trip current independent of ambient temperature. This has made them the #1 choice for OEMs in demanding applications.

But that’s not all - thanks to the lack of a energy consuming bi-metal element, the HY-MAG MCBs also have a much lower internal resistance, typically 45% less. That’s significant because it means real energy savings. These energy- and the environmental savings add up to considerable amounts over the lifetime of the products. And today, when cost of electricity and concern for the environment is high on the agenda, this is really something to keep in mind. |

|

|

|

| If you care about energy savings and sustainability, contact us and we will be glad to discuss how you can contribute by making the right choice of circuit breaker – and get the best possible protection at the same time! |

|

| You get this newsletter since we have your contact details in our CRM system. If you wish to unsubscribe from the newsletter, please use link in top of the newsletter. If you wish to be removed from our CRM system, send us an email at info@emcomp.se |

|

|

|