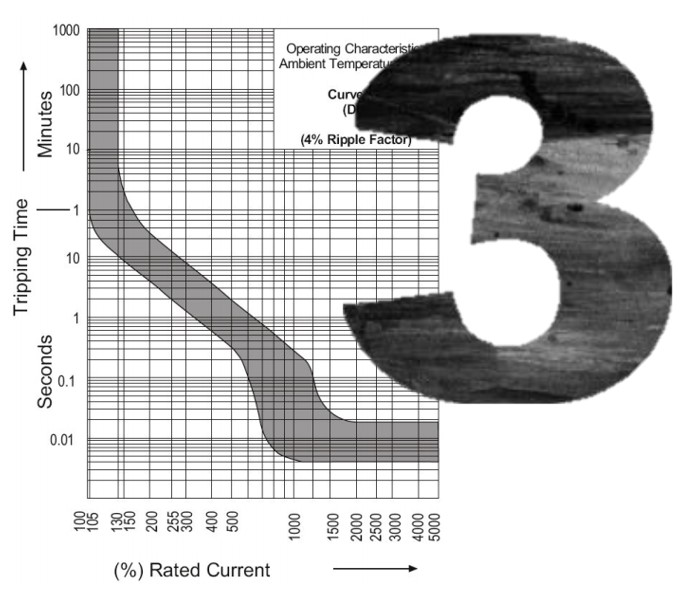

| Thermal circuit breaker only works properly in room temperature. But our products keep rated current regardless of the temperature is -40 or +85 degrees ambient. So the big advantage is that no de-rating needed. |

|

|

|

|

Our products keep rated current regardless of the temperature is -40 or +85 degrees ambient.

|

|

|

|

Thermal circuit breaker you are only allowed to load continuously to 80% of the rated current (the 80% de-rating rule) while our products are rated to be loaded at 100% of rated current.

|

|

|

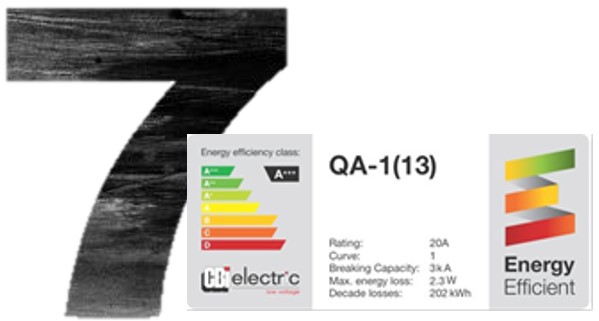

The temperature independence give us the possibility to build a circuit breaker thinner. What means that our DIN rail mounted circuit breakers have 13mm instead of common 18mm. Keep in mind also that space saving is cost saving in many cases.

|

|

|

| When a thermal circuit breaker trips due to an overload the bi-metal strip needs to be cooled down before it can be switched on, this is not the case for a Hy-Mag product. Your important loads can immediately be switched on again. |

|

|

|

|

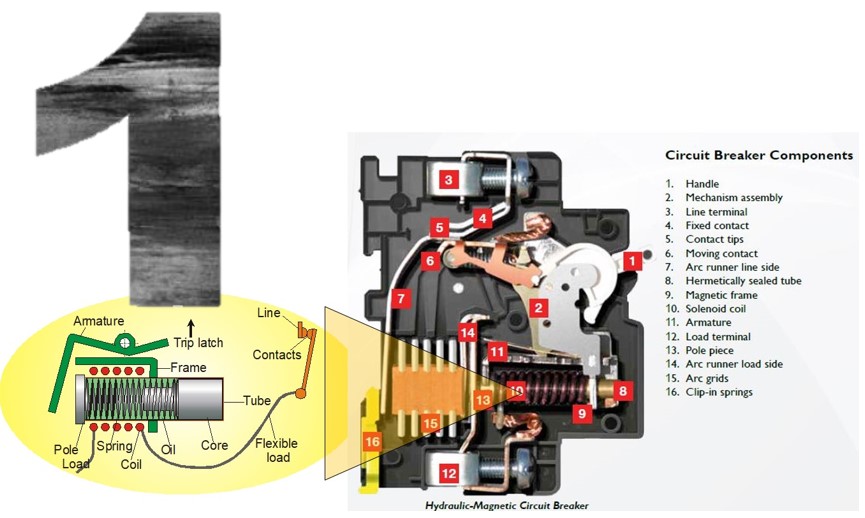

| Thermal circuit breakers are in general designed for AC but used also for DC. A DC voltage is more difficult to handle for a circuit breaker, since there is a risk of the arc not being extinguished when switching the circuit breaker. Therefore our Hy-Mag products are designed in different ranges, dedicated for DC or AC depending on your application. |

|

|

|

|

|

| It’s very important to not waste energy, both from an environmental point of view as well as from a cost point of view. The bi-metal strip on a thermal circuit breaker always create a certain heat which means losses. In general, the internal resistance in a Hy-Mag circuit breaker is around 45% lower. |

|

|

|

|

| The sensing device on a thermal circuit breaker is the bi-metal strip. This will over time be exposed to air, humidity and different types of pollution that will affect the functionality over time. This is not the case for the Hy-Mag circuit breaker since the sensing mechanism is hermetically sealed. |

|

|

| In general our products are certified both to the highest European industrial standard for circuit breakers, IEC 60947-2 as well as UL listed according to UL489 or UL489A. |

|

|

It all started in USA 1915 when George Heinemann invented the technology. The manufacturing in South Africa started in 1949 at Heinemann SA. The company changed name 1985 into CBI, Circuit Breaker Industries. CBI is today a leading manufacturer of hydraulic magnetic circuit breakers. Emcomp is the geographical partner for CBI products in Europe and we have also for the last 20 years provided CBI solutions to the global telecom power market.

|

|

|

|

| You get this newsletter since we have your contact details in our CRM system. If you wish to unsubscribe from the newsletter, please use link in top of the newsletter. If you wish to be removed from our CRM system, send us an email at info@emcomp.se |

|

|

|